Industrial Automation, traditionally, signifies the journey from mechanization (human intervention required to operate machinery) to computerized Automation control. This need came up to ensure high quality, accuracy, precision, and performance of industrial processes. However, in the context of Industry 4.0, with growing use of sensors & actuators coupled with exponential increase in computing power – a new journey has begun. This journey is from Control Automation (PLC controlled industrial processes) to data based decision-making. It is a journey which starts from Data acquisition to Data utilization.

Opportunities and Challenges

Out of the entire gamut of Industrial players (both discrete and process industries), it is mainly Original Equipment Manufacturers (OEMs), Manufacturing Suppliers, and Instrumentation companies are embracing this change and are at different levels of maturity. These companies provide B2B offerings in the Industrial domain with right mix of hardware and firmware. They offer sensors, data loggers, industry equipment, instrumentation, etc., and have SCADA, DCS, HMI systems as well.

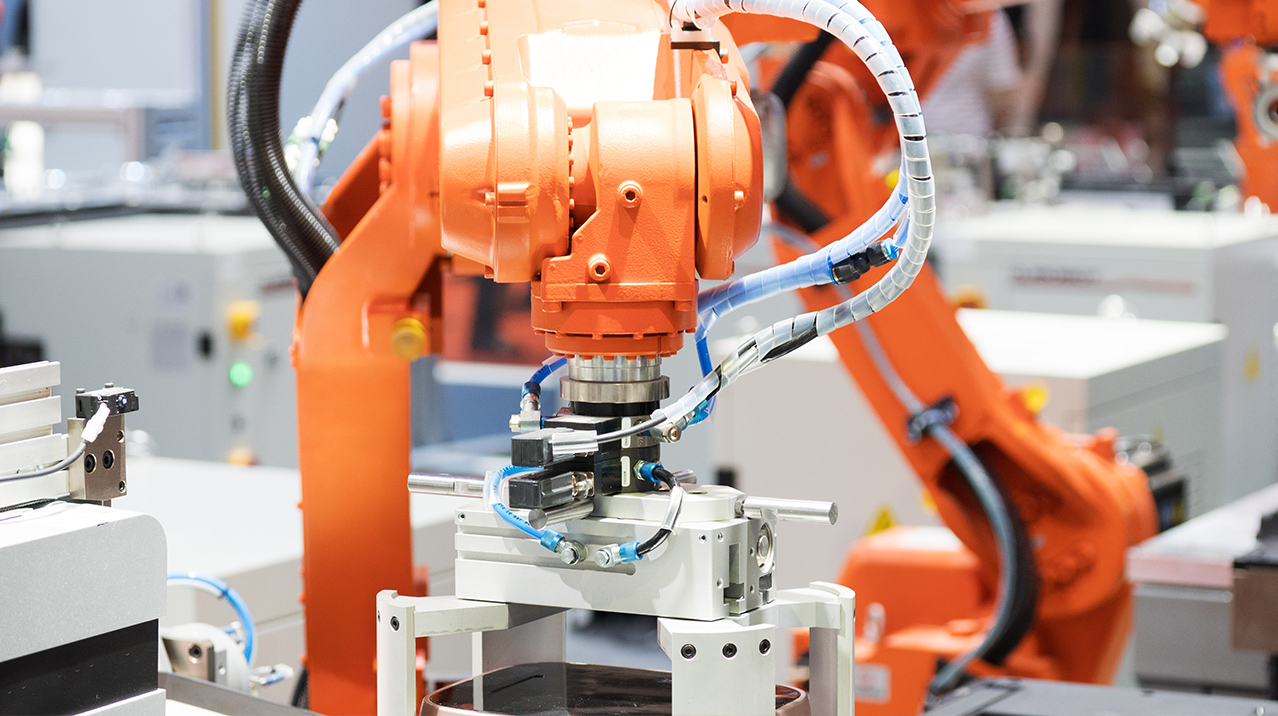

OEMs assist industry in the development and manufacturing of products & systems. They provide components for the products of another company and are highly committed to quality & service in light-duty as well as heavy-duty manufacturing. They provide smart equipment sensors, which make asset intelligence seamless. They can make any machine, motor, pump, or gearbox a smart device.

Such companies are certified & registered manufacturers of controls for industrial applications. They specialize in the control & measurement of fluids, vibration, etc., for various control instrumentation needs. These could be the productivity-enhancing instrumentation & control companies, which design and manufacture a complete line of meters, monitoring devices, data loggers, electronic balances, scales, weighing indicators & controllers for service & industrial applications, and also monitoring equipment for various professional markets.

Many manufacturing companies are leading global suppliers in the automotive and industrial sectors. Their portfolio comprises of high-precision systems & components for engine, chassis, and transmission applications as well as plain and rolling bearing solutions for many industrial applications. One genre would be specializing in Roller and friction bearings, Engine elements, Linear guides, precision products, friction management, power transmission, industrial equipment, heavy industry, machine tool, or positioning control. Others include companies that design power transmission & engineered products; which improve efficiency & reliability of global equipment and machinery for moving the world forward.

Overall, all OEMs specialize in Manufacturing & Technology and research & development of technologically advanced products in the global marketplace for industrial applications. These companies have quality-certified manufacturing/assembly plants and technical centres in various locations. However, these companies are facing a critical challenge to increase their Overall Equipment Efficiency (OEE) score which requires a strong handshake between OT & IT.

Bridging the gap using IIoT & Data Analytics

For many of our Manufacturing customers, our project teams have been able to bridge this gap and create strong synergy between the OT & IT teams.

With multiple Instruments & edge devices on the field, our teams have been able to successfully connect these devices to cloud & amalgamate the data in the form of data streams, data blobs & data warehouses, thereby providing a single source of truth to decision-makers. Backed by our industry & technology expertise in understanding the data being generated from multiple instruments, and their correlation with each other - we were able to generate actionable insights using powerful reporting tools like Power BI & Tableau.

Businesses run on Key Performance Indicators (KPIs) and business decisions can be made only when all the data resides at a single location and that the reports & KPIs are generated from it. Our project teams have helped many of our customers to get a unified view of their important KPIs. For illustration, our teams helped a Medical equipment manufacturer build a robust Cloud-based IoT platform that enables real-time Equipment health monitoring.

Whether it is writing device driver interfaces for hardware, architecting an Enterprise Extract-Load-Transform (ETL / ELT) solution, or developing visually appealing dashboards & charts, our project teams have worked with customers across multiple industries & domains to get these in place. Each Business Unit within an organization have their own rules & challenges from various perspectives - like location, network firewalls, bandwidth, sources of data, etc. Our teams have provided be-spoke solutions such as real-time IIoT platform, and Predictive maintenance of assets; to the customers to tide over such challenges.

For many of our customers, we have also been able to generate algorithms from their past data to derive Predictive Maintenance (PredM) models, which can be used to predict KPIs like Power Output, Faults, Equipment Efficiency to build solutions like Power generation forecasting. As a result of implementing a strong IT strategy revolving around the data, all asset intensive companies can run their operations more efficiently & save costs.