About Client

The instrument engineering company manufactures data acquisition systems (DAQ) which enable critical testing, measurement and monitoring applications for aerospace, industrial and automotive industries. The DAQ systems –

- acquire data in real-time for different physical quantities using sensor technologies

- enable high measurement accuracy due to patented technology

- integrate with various Enterprise software applications like LabView, Visual Studio .NET, and more

The client wanted to deliver a complete sensor-to-software system, that is easy to use with a simple plug and measure concept.

Challenge

Each device / sensor has its unique technology, serves a different purpose and therefore has a separate data acquisition platform that works best for that product. However, their end customers, who are large industrial Enterprises, may need one or multiple devices / products for their applications and therefore need to work with different platforms. There were different data acquisition platforms in use which meant –

- Our client has dozens of hardware & software systems for providing services to their enterprise clients

- Large effort and resources required to maintain these platforms

- Time-to-market is also slow & lengthy

- The scattered product portfolio leads to a disconnected sales process & low customer perception

- Lack of standard Functionality across platforms

Client’s roadmap for solution

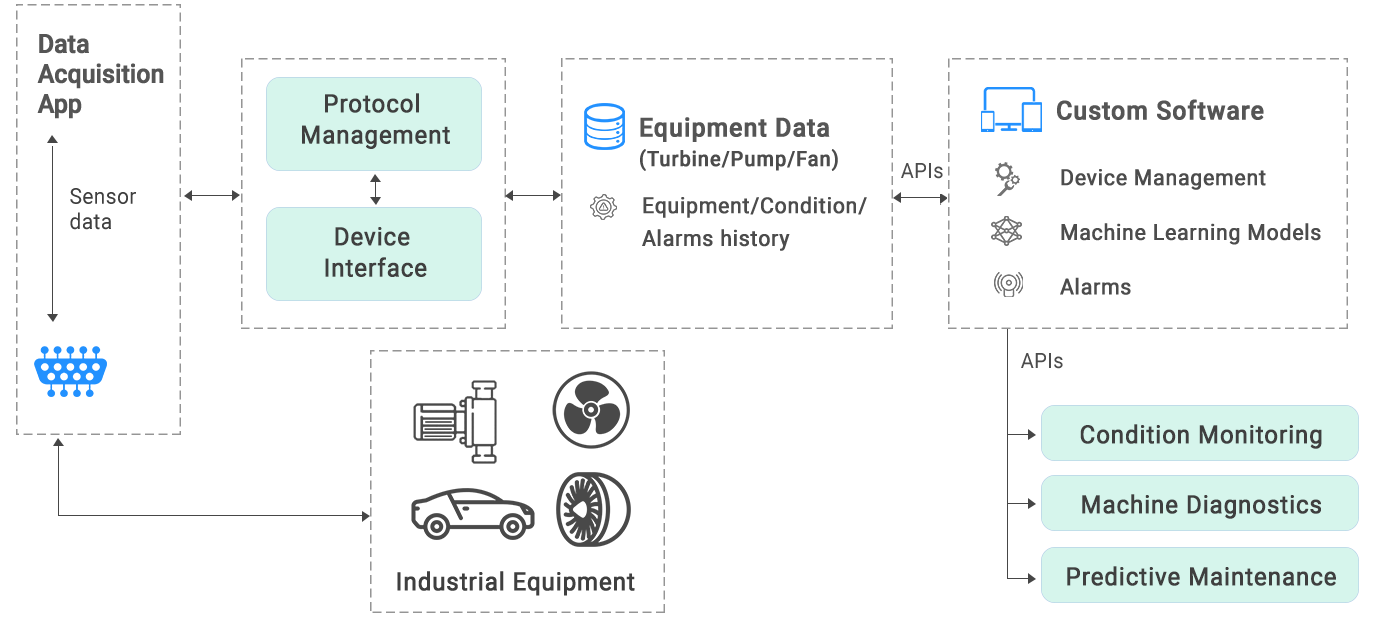

To enable the simple plug and measure capabilities for their clients, the hardware needs to be able to acquire data from a wide variety of sources (different data acquisition platforms). It needs to be processed in real-time and made available to a variety of applications for further analysis.

This requires building an end-to-end data engineering capacity throughout their data acquisition, organization, analytics, and action procedures.

Condition monitoring of industrial equipment

Condition monitoring of industrial equipment

Platform implementation as an outcome

Saviant partnered with the Instrument Engineering company in developing the complete robust condition monitoring platform with smart data analytics & AI capabilities. With a team of 20 technology consultants, developers working on .Net core, GraphQL - New API technology, OPC UA to represent Device objects in client server mechanism, and to communicate with device, with device discovery protocols like MQTT.

This common platform captures data from the various sources & platforms in real time, orchestrates it and delivers it to a variety of applications via APIs. This achieved –

- A complete sensor to software platform

- Opening interfaces to customers across various levels – device, measurement file or application

- Standardization across platforms

- Platform independence – Windows, Linux, MacOS etc

- Scalability

- Security

This modern platform therefore enabled a truly plug and measure capability for the customer across different products and their platforms.