RestorationCo is a professional firm based in New York, USA. Their team consists of engineers and architects who inspect, restore and preserve the exterior of buildings and infrastructures. Since 1981, they have restored thousands of buildings in and around New York City. In 48 years of operations, they have contributed to the preservation and restoration of thousands of architectural structures. They have won the prestigious Lucy G Moses Award viz. the ‘Oscar’ of the preservation community, consecutively from 2010-2016. With numerous architectural preservations taking place every year, RestorationCo needed automation in their daily operations to ease their efforts.

Here’s how they leveraged automation and used AI in their preservation process. It reduced the process duration from a 50-60 weeks to just 5-10 weeks.

Building inspection: From manual to automated

RestorationCo lacked an automatic process to identify and document the faults in construction. Theirs was a time-consuming and lengthy process. The team used harnesses to propel themselves around the buildings. They clicked pictures of multiple facets of buildings and fed them manually into the system. The engineers and architects had to manually sort out several thousand pictures at once. The construction faults were identified after looking at such pictures.

Today, this entire process is automated. This automation allows the engineers and architects to use their specialty elsewhere. The non-technical staff conduct this process, using drones as it does not demand any special skills to inspect buildings.

Automation Advantages

Automation has replaced the physical inspection process. Drones capture pictures of multiple facets of the building. They are entered into the system and sorted automatically. With the in-built feature of drones, these pictures get ordered according to the sequence they are clicked. This reduces the duration of the inspection process considerable. While it took several months to inspect the faults in the construction, it simply takes a couple of weeks today. The architects and engineers need not be present for the inspection.

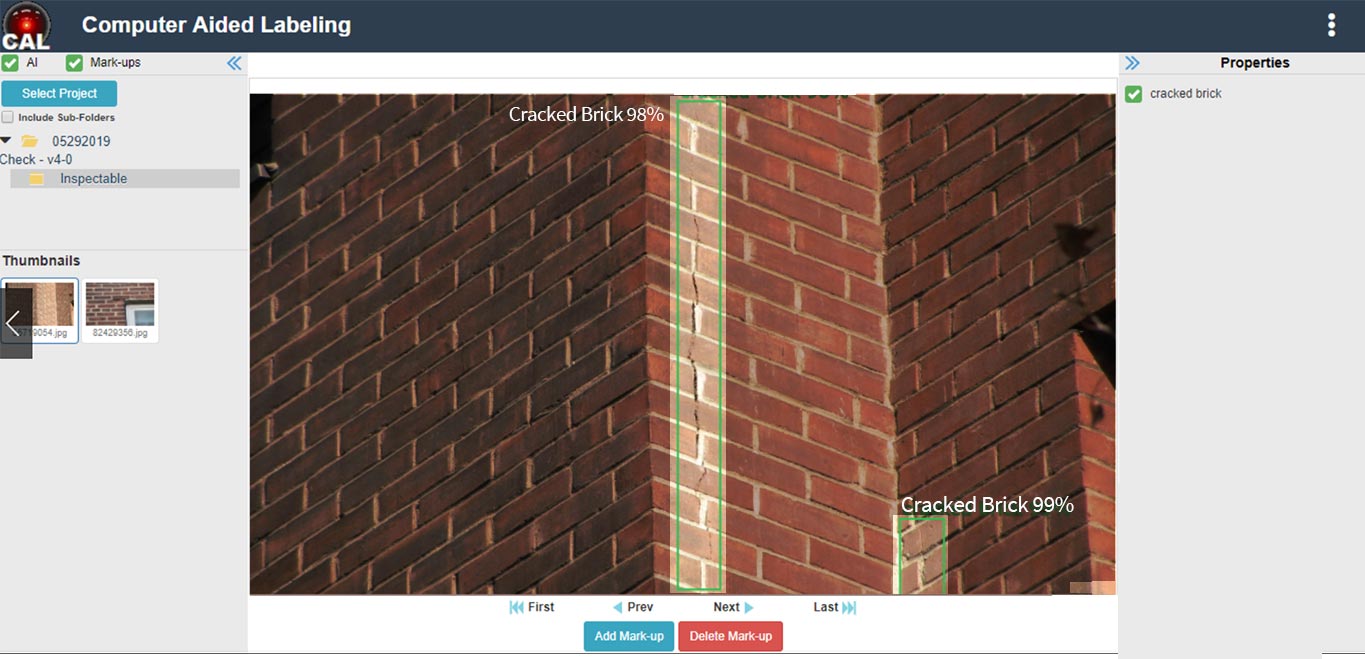

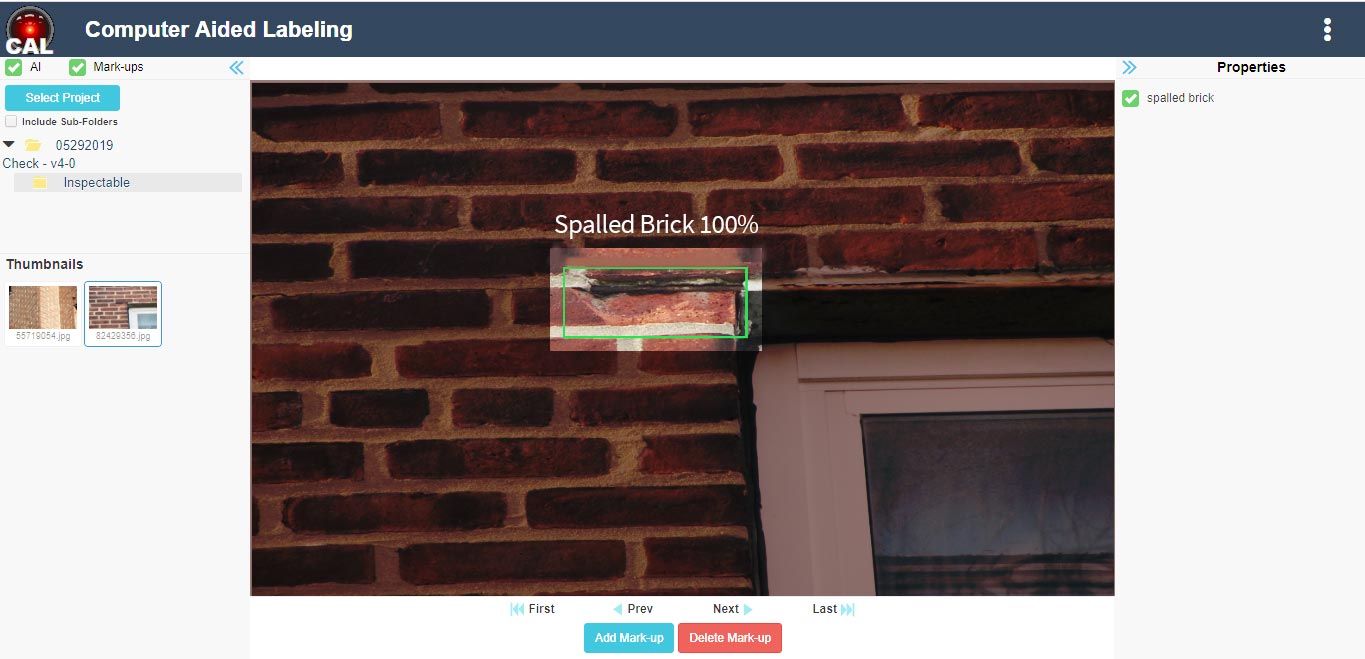

The Solution: AI enabled Object Detection and Localization

RestorationCo enabled its system with Artificial Intelligence to improve and speed up its restoration and preservation process. Automation enabled the sequencing of building pictures. Machine Learning algorithms were run on these pictures to detect objects and faults. It identified construction faults with symptoms such as cracks, spalls, biological growth, broken glass, bent/deteriorated sheet metal etc. Today, the solution can identify the cracks, spalls, discolouration, deterioration etc and identify its degree in percentage. For e.g. 95% crack in concrete. Further data analysis of these photographs can visualize patterns, trends and correlation of the symptoms on all photos.

Thinking to automate your business operations quickly using AI? Let's do a quick PoC.

Drop a note, Right away!