InstrumentationCo is a leading supplier of productivity enhancing instrumentation and controls. Since its establishment in 1962, InstrumentationCo has catalogued and offered 100,000 engineering instruments which measure and control temperature, humidity, pressure, strain, force, pH, conductivity etc. These instruments also provide customers with a complete line of data acquisition, electric heating, automation, highly engineered products as well as customized solutions. The organization’s primary offering also includes an ‘Enterprise Gateway’ (EG), a tool designed to help gain optimal control and insight into the process. This Gateway captures data from the installed devices. However, InstrumentationCo’s existing system was on-premise and lack scalability. Thus, the company was not able to live up to its promise to its customers of ‘providing facilities to facilitate their needs’. Here were the challenges-

No visibility of devices

InstrumentationCo’s Enterprise Gateways were unable to obtain real-time visibility of the devices it consisted of. These devices were linked to machineries and equipment which conducted industrial tasks for its customers. But the lack of sophisticated connectivity between the device and the EG could not generate condition data of the device. In case of any abnormality in the device, no notifications were triggered to the system user. It also did not provide real-time information on the device connectivity, duration of connectivity and the actions performed on it. The industrial tasks were affected due to this inefficiency and inaccuracy. The upkeep and maintenance of the devices had become a challenge due to this lack of visibility. It also could not establish and maintain bi-directional communication between the devices and EG.

Unable to connect multiple EGs

InstrumentationCo’s exisiting legacy system was unable to scale up. It allowed only one EG per user. It had a low capacity of storage for the data generated by devices. Since the number of devices could increase, the system did not permit data collection and storage from increased devices. Also, because it was an on-premise system, it was unable to provide access for multiple users at once. This made the task of monitoring the devices a challenge and affected the employee and process productivity.

Increased Downtime

The on-premise legacy system had the possibility of facing a system shut down and affecting monitoring of devices. In case of maintenance and system failure, it would experience a downtime and hinder the on-going process. Since the condition of devices was of an utmost importance for further activities, InstrumentationCo and its customers could not afford the system’s unavailability.

Manual upgrades

InstrumentationCo’s legacy system required manual upgrade and updates. They were time and cost consuming and interfered with the system’s up time. The system had to be shut during regular maintenance cycles. It affected the data logging and monitoring process for the connected devices. It was the same situation in case of adding new features and facilities to the system.

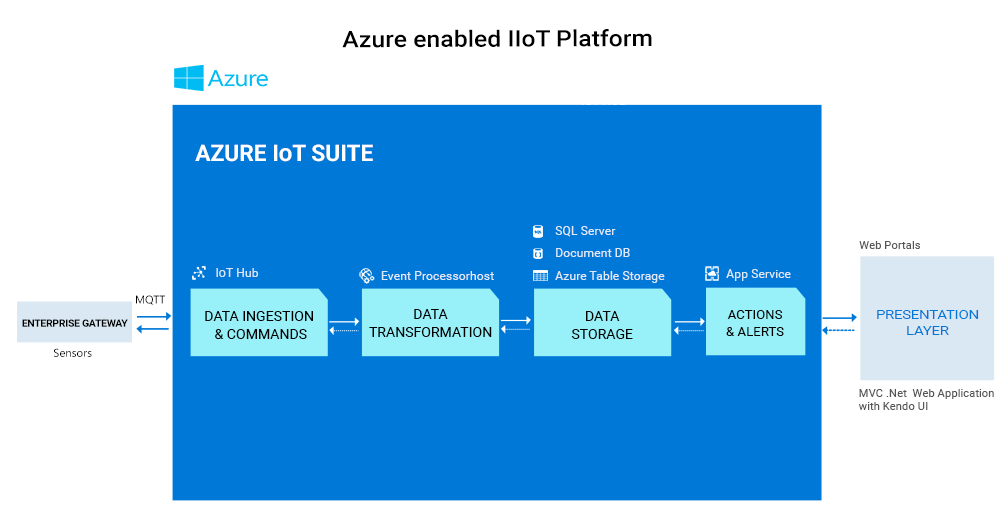

The Solution: High-end, Scalable Cloud based IIoT platform

An asset intensive requirement such as this needed a robust and scalable infrastructure. Microsoft Azure Cloud Platform was leveraged which could collect, store and manage a huge volume of data pouring in from multiple devices. The IIoT platform was able to establish a bi-directional communication system between the devices, EG, cloud platform and vice versa. It ensured that the devices communicated their status and condition to the user monitoring the device and control its behaviour. An alert system was fit into the new solution which sent an email notification to the user in case of abnormality in devices’ condition. It made sure that maximum up time of devices and no disturbance to the existing process. The conditional abnormalities include temperature threshold values, dead devices, device malfunctioning and similar such events. Due to this Azure based IIoT Platform, the existing system has scaled up to connecting 100+ Enterprise Gateways and operates with a data collection frequency of 1 minute to 1 hour and houses up to 150 GB of data records. It collects data from 3000+ connected devices and stores 1 million data records every year. This robust and scalable solution has empowered InstrumentationCo to provide better service to its customers. The goal of providing facilities to facilitate customers is already a reality.

Need real-time visibility over your assets health? Talk to our IoT Specialist today!

Schedule a Consultation now