AI-Augmented Digital Twins: How Zero-Shot Failure Prediction Minimizes Downtime and Builds Trust

- Home

- Blog

Deepak Singh

Praful Dandgawal

Praful Dandgawal

|

Introduction: Downtime is more than a technical problem - it’s a trust problem

In the world of industrial equipment, downtime doesn’t just disrupt operations - it damages trust. When a critical asset fails, customers lose productivity, miss deadlines, and face rising service costs. According to industry reports from Deloitte and McKinsey, 82% of industrial companies have experienced unplanned downtime in the past three years, leading to a 10 - 20% drop in production capacity.

For OEMs, these failures are no longer just service challenges - they’re strategic risks. Today’s customers expect intelligent equipment that is not only reliable but predictive, adaptive, and resilient. This evolution in customer expectations demands a shift from reactive maintenance to proactive, intelligent systems.

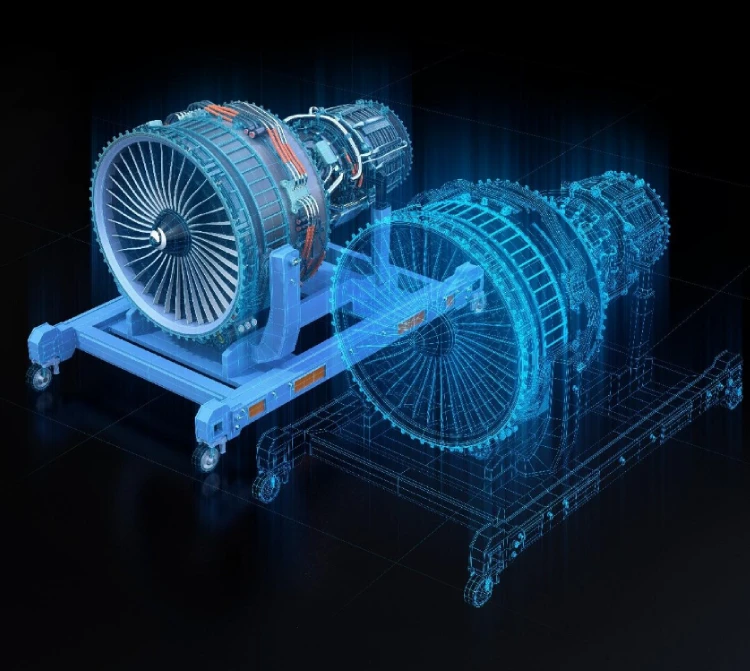

Enter: AI-augmented digital twins - a powerful approach that leverages real-time data and artificial intelligence to transform how OEMs predict, prevent, and respond to failures.

Problem statement: Traditional monitoring can’t predict the unknown

Most OEMs already use monitoring tools to flag known issues. But what happens when a failure has never occurred before? Traditional systems fall short, leaving teams unprepared.

Here’s the gap many OEMs are struggling with:

- Customers demand high reliability and proactive support - but are often let down by reactive service models.

- Engineering and product teams are stuck firefighting field failures, delaying innovation and product releases.

- Digital transformation initiatives , like SaaS and servitization, stall when legacy monitoring tools can’t scale or adapt.

The inability to anticipate unknown faults - especially across global deployments - results in costly downtime, delayed upgrades, and lost customer confidence.

The solution: AI-augmented digital twins with zero-shot failure prediction

AI-augmented digital twins elevate traditional twins by embedding intelligence into their core. Unlike standard models that simulate “ideal” performance, AI-driven digital twins learn from real-world operational data, continuously evolving their understanding of machine behavior.

With zero-shot failure prediction, OEMs gain the ability to detect anomalies - even without historical fault data. This enables them to:

- Uncover unknown risks: AI identifies early signals of failure before they escalate.

- Run ‘what-if’ simulations: Stress-test machines under digital conditions before field deployment.

- Deliver proactive service: Prevent unplanned downtime with intelligent, predictive maintenance.

- Accelerate innovation cycles: Free engineering teams to focus on product development, not damage control.

This shift transforms operational strategy. OEMs move from responding to failures to preventing them, delivering exceptional reliability and customer trust.

Why consulting expertise is essential

While platforms like Azure, AWS, and Siemens offer the digital twin infrastructure, technology alone isn’t enough. Success lies in execution.

A specialized digital twin consulting partner helps OEMs:

- Design scalable architectures that connect edge data, cloud analytics, and Generative AI models.

- Integrate with legacy systems and ensure seamless data flow from machines to decision-making platforms.

- Prioritize business value, aligning digital twin capabilities with product strategy, service goals, and revenue models.

- Accelerate implementation with proven frameworks that reduce risk and time-to-value.

For CTOs, product heads, and engineering leaders, this expertise is what transforms AI from a promising concept into a production-ready advantage.

Call to action: Make reliability your competitive edge

AI-augmented digital twins offer OEMs a new paradigm - zero-shot failure prediction that turns data into foresight. The impact?

- Fewer service disruptions

- Faster innovation cycles

- Deeper customer loyalty through trust and performance

At Saviant Consulting, we help industrial OEMs turn complex machine data into intelligent, scalable solutions. From designing digital twin architectures to embedding AI-driven insights, we ensure your operations become smarter, faster, and more resilient.